Heat Exchangers: Thermal Transfer Technology Applied in Industrial and HVAC Fields

2023-10-24 | Heat Exchanger

A heat exchanger is a device used to transfer thermal energy (enthalpy) between two or more fluids at different temperatures, between a solid surface and a fluid, or between solid particles and a fluid, often in cases of thermal contact without external heat and power interaction. Heat exchangers are widely employed in various fields, including space heating, refrigeration, air conditioning, power plants, chemical plants, petrochemical plants, oil refineries, natural gas processing, and wastewater treatment, among others.

Types of heat exchangers include:

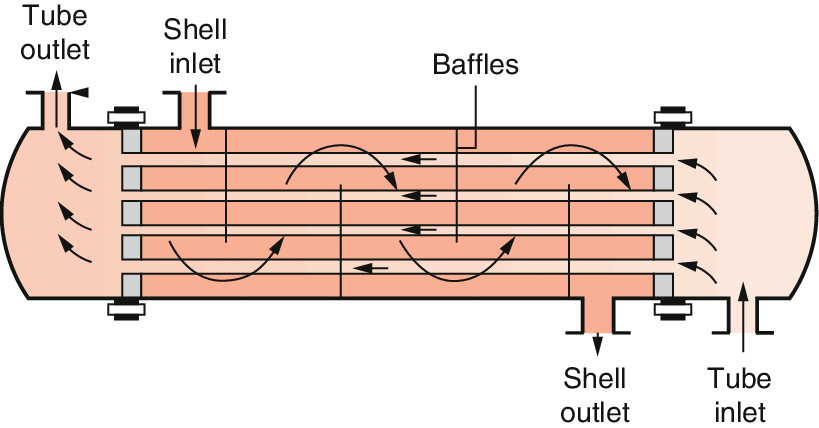

Shell and Tube Heat Exchangers

Shell and tube heat exchangers consist of a series of tubes containing the fluid to be heated or cooled. Another fluid passes over these heated or cooled tubes to provide or absorb the necessary heat. This type of heat exchanger is typically used in high-pressure applications (pressure greater than 30 bars, temperature higher than 260 degrees Celsius).

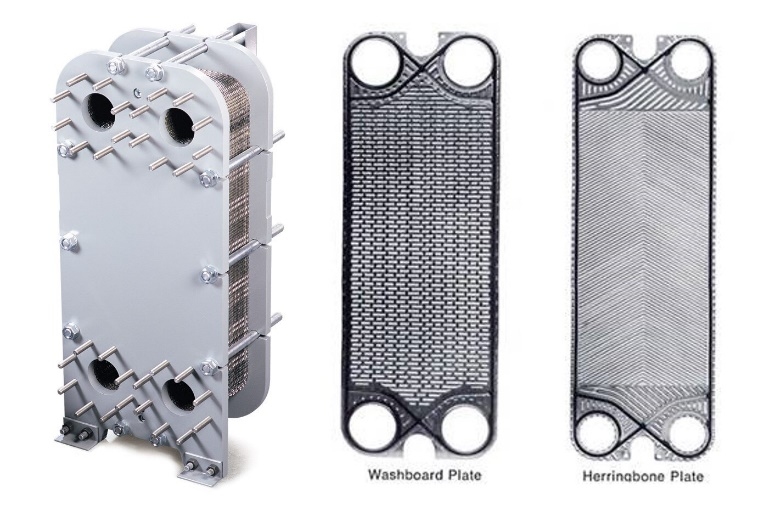

Plate Heat Exchanger

A plate heat exchanger consists of numerous thin, slightly separated plates with a very large surface area and small fluid channels for heat exchange. In HVAC applications, this type of large heat exchanger is known as a plate and frame heat exchanger.

Plate and Shell Heat Exchanger

This type of heat exchanger combines the technologies of plate heat exchangers and shell and tube heat exchangers. It offers high heat transfer efficiency, high pressure, high operating temperatures, compact size, low fouling, and close approach temperatures. It doesn't use gaskets, providing leak-proof safety under high pressure and high temperature conditions.

Rotary Wheel Heat Exchanger

This type of heat exchanger uses an intermediate fluid or solid storage to store heat and then moves it to the other side of the heat exchanger to release the heat.

Plate Fin Heat Exchanger

This type of heat exchanger uses channels with fins to increase the device's effectiveness. Usually made from aluminum alloys, this type of heat exchanger has high heat transfer efficiency and is mainly used in low-temperature services, such as natural gas, helium, and oxygen liquefaction plants, air separation plants, as well as in the transportation industry for automotive and aircraft engines.

Pillow Plate Heat Exchanger

Pillow plate heat exchangers are typically used for milk cooling in large stainless steel tanks, where almost the entire surface of the tank can be integrated with this type of heat exchanger, eliminating gaps that can occur between externally welded pipes. The relatively flat surface of this heat exchanger makes it easy to clean, especially suitable for sterile applications.

Microchannel Heat Exchanger

A microchannel heat exchanger is a multi-channel parallel flow heat exchanger consisting of inlet and outlet manifolds, porous tubes with inner diameters less than 1 millimeter, and fins. This type of heat exchanger features high heat transfer to fluid ratio, low refrigerant load, small size, and low airside pressure drop. It is widely used in the automotive industry, such as automotive radiators, as well as in the HVAC industry for condensers, evaporators, and cooling/heating coils.

HVAC and Refrigeration

Heat exchangers find extensive applications in refrigeration and HVAC systems. This type of heat exchanger is often referred to as a coil due to its internal pipes, which are typically serpentine or referred to as condensers in refrigeration. These heat exchangers are usually tube-in-fin type.

Self-Cleaning

Spiral heat exchangers are commonly used for heating fluids containing solids, making them prone to fouling. Due to low pressure drop, spiral heat exchangers can handle fouling issues more effectively. They employ a "self-cleaning" mechanism, where fouling surfaces increase local fluid velocity, increasing fluid resistance on the fouling surface, aiding in the removal of blockages, and keeping the heat exchanger clean.

The fouling rate in a heat exchanger is determined by subtracting the redeposition/inhibition rate from the particle deposition rate. This model was initially proposed by Kern and Seaton in 1959.

Crude Oil Fouling. In commercial crude oil refining, crude oil needs to be heated from 21°C (70°F) to 343°C (649°F) before entering the distillation column.

Cooling Water Fouling. Cooling water systems are susceptible to fouling due to high concentrations of total dissolved solids and suspended colloidal solids. Since the tube wall temperature is higher than the fluid temperature, dissolved solids precipitate locally on the heat exchange surface. Low fluid velocities (less than 3 feet per second) lead to the deposition of suspended solids on the heat exchange surface. Typically, cooling water is on the tube side of shell and tube heat exchangers, as it's easier to clean. To prevent fouling, designers usually ensure cooling water velocities greater than 0.9 meters per second and maintain fluid temperatures below 60°C (140°F).

Conclusion

Heat exchangers are indispensable key technologies in modern industrial and HVAC fields. These diverse types of heat exchangers play a vital role in various applications, from air conditioning to chemical plants, and even the automotive industry. They not only provide efficient heat transfer but also offer safety and reliability when handling fluids at different temperatures and pressures.

In the continually evolving world of technology, heat exchanger design and technology continue to innovate. Through ongoing research and improvements, heat exchangers will remain essential tools for industries in enhancing efficiency, saving energy, and achieving environmental goals.