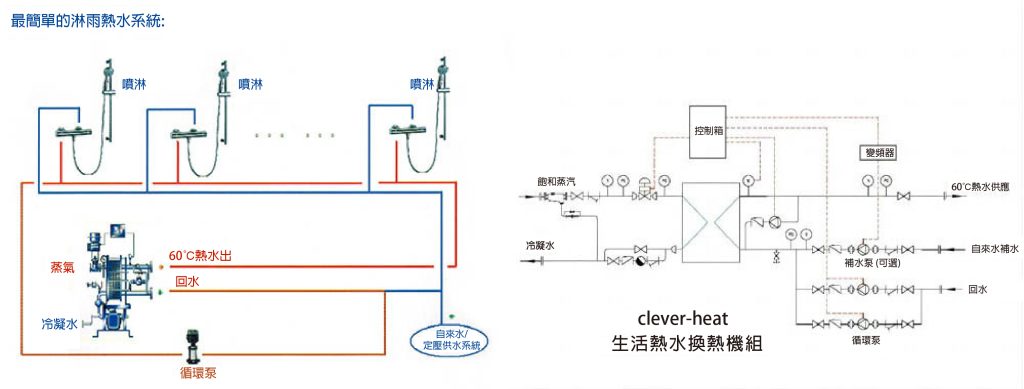

Small-Scale Steam Rapid Heat Exchange System

This system is designed to address situations where a large number of employees may simultaneously open taps, requiring an immediate supply of stable hot water. It should also accommodate scenarios where some employees might turn off taps simultaneously, ensuring a constant water temperature. Additionally, it should not require the release of a large amount of cold water when taps are first opened, ensuring water temperature safety and preventing scalding accidents. The water quality must meet sanitary standards, avoiding direct contact with industrial steam and minimizing the retention time of hot water. The heat exchange equipment should occupy minimal space in the utility room, have low scaling rates, require minimal maintenance, and include features like unmanned operation and alarm notifications.

Energy Source for the Heating System:

For non-standard systems, utilizing high-temperature wastewater for heat exchange, such as high-temperature steam condensate, is a priority. If insufficient, additional heating can be provided by steam. This approach saves steam costs and reduces the expenses related to discharging cooled wastewater.

System Control:

The control system gathers signals related to the temperature and pressure of both the primary and secondary sides, pressure differences in the dirt separator, outdoor temperature, flow rates, and the manual/auto status of circulation pumps and makeup water pumps. These signals can be transmitted to a monitoring center through a remote terminal control system for remote control. Controlled parameters include secondary side supply water temperature, pressure, and supply-return water pressure difference.

Common Control Strategies:

- Climate Compensation and Crosswise Water Supply Function: The programmable logic controller automatically sets the secondary side supply water temperature based on outdoor temperature changes and the local heat load curve. The actual value of the secondary side supply water temperature is compared with the set value through PID adjustment, and the controller output signal regulates the electric valve for temperature control.

- Automatic Makeup Water: A pressure sensor installed on the secondary side return pipe measures pressure signals. Comparison with the set value allows the output of control commands to start/stop or vary the frequency of the constant-pressure makeup water pump.

- Automatic Pressure Relief Function: The system can select either pressure expansion tank XinXin buffer system’s hot water expansion relief or pressure relief via electromagnetic valve method. For absolute safety, both methods are equipped with safety valves.

- Supply and Return Water Pressure Difference Control: A pressure differential bypass valve is required in the supply and return water system, usually installed between the manifold and the collector. This ensures the water circulation volume when the load decreases and the return water pressure decreases. Frequent changes in load affect the working state of the water pump, impacting its lifespan. In this situation, the pressure differential bypass valve is opened to ensure the system’s water circulation volume. Moreover, by not controlling the supply and return water pressure difference, water is preferentially returned from the nearby user when they have a large load. With the pressure differential bypass valve, most users still choose variable frequency circulation valves, increasing system stability. The pressure difference can be set on the site controller or remotely.

- Power Failure Protection Function: After a sudden power outage, the electric valves on the primary side will automatically close the heat source (e.g., steam) to prevent over-temperature and vaporization, which could damage the heat exchanger and pipes. The controller and inverter will automatically reset, maintaining the settings and operating parameters before the power failure.

- Self-Inspection Function upon Startup: There is a setpoint for secondary return water pressure. If the secondary-side pressure does not reach this value, the circulation pump cannot start, only the makeup water pump can operate. When the setpoint is reached, the circulation pump can start, and the heat exchange system begins self-checking in sequence.

- Low-Pressure Protection: If the secondary side return water pressure drops below the set value, the circulation pump stops automatically.

- Over-Temperature Protection: If the primary-side heat source temperature exceeds 180 degrees Celsius, the electric valve will close automatically, and an alarm signal will be generated.

- Overpressure Protection: If the secondary supply water pressure exceeds the set value, it will be vented automatically, and the electric valve on the primary side will close.

- Monitoring Water Tank Liquid Level: When the water tank’s liquid level falls below the super-low line, the makeup water pump stops automatically, and an alarm signal is generated.

- Time Control Program: It allows scheduled system startup and shutdown, energy-saving mode, and custom heating schedules for daily, weekly, and monthly periods.