Tell us your requirements, and we will tailor an industry solution for you!

We take pride in utilizing our professional heat transfer technology, practical experience, and innovative thinking to optimize every client's system. From the initial design to product installation and maintenance, we are committed to actively participating in the entire process. It is our honor to be involved in ensuring the success of your project and providing excellent support throughout its lifecycle.

Research and Innovation

Research and Innovation

Talent is the foundation of innovation. We continuously engage in research and development activities in areas such as high-temperature and high-pressure resistance, fatigue resistance, corrosion resistance, scale and fouling prevention, etc. Our aim is to develop innovative, customer-centric, and cutting-edge new products and technologies that lead the future market.

Innovation is the soulWe have established an outstanding innovation system through effective collaboration mechanisms, operational mechanisms, and incentive mechanisms to harness our full innovation capabilities. The accumulated innovation capacity and solutions continuously serve customers with increasingly demanding quality requirements. We contribute wisdom and strength to the construction of a green, energy-efficient, and environmentally friendly society.

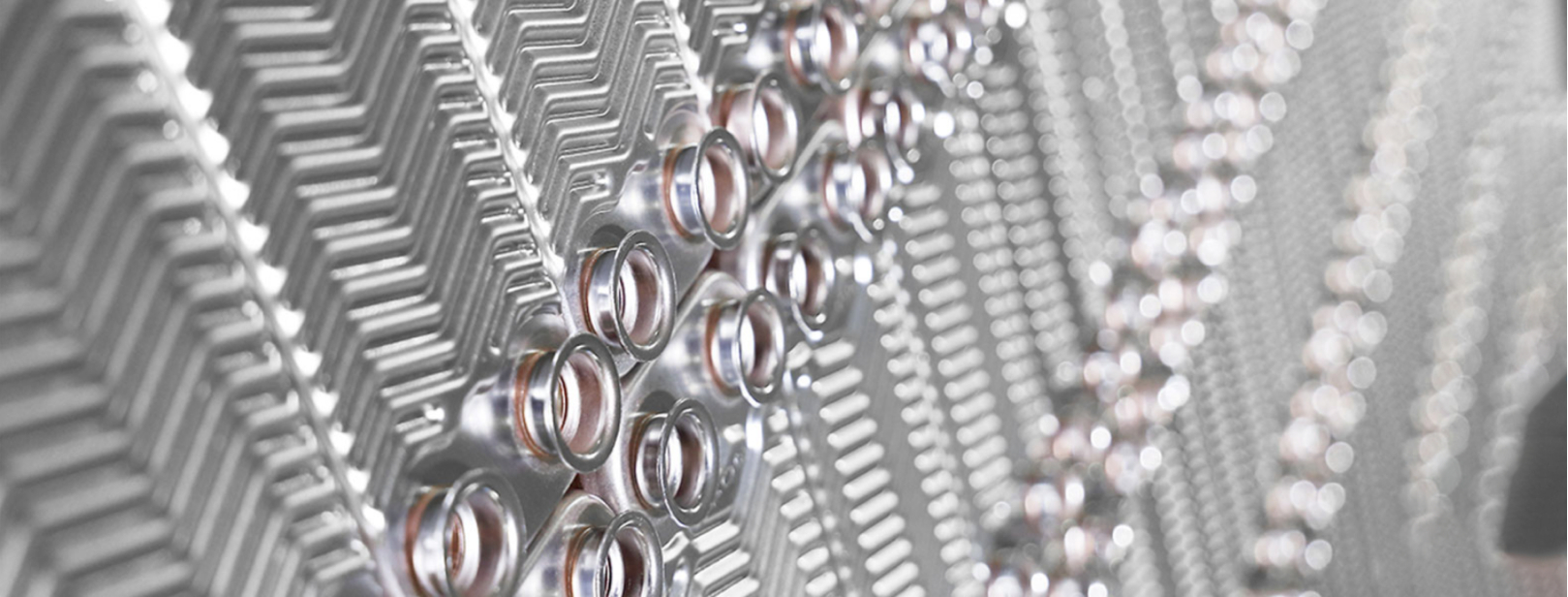

Core TechnologyOptimized and innovative plate design Revolutionary heat exchanger technology trends The unique plate design and manufacturing technology make the heat exchanger structure more compact, significantly increasing the effective heat exchange area and energy efficiency. The reduced number of plates required for the same heat transfer reduces raw material consumption, lightens the product weight, and contributes to energy savings and emission reduction. These technical advantages will bring you more returns.

Stainless Steel - The ideal material for heat exchanger

manufacturing

Stainless Steel - The ideal material for heat exchanger

manufacturing

Safe, durable, and corrosion-resistant Today, heat exchangers are made of different materials. Choosing the right material plays a crucial role in functionality and lifespan. Stainless steel has gained a reputation for its application in various advanced technologies and products. As an advocate of stainless steel heat exchangers, we have been manufacturing plate heat exchangers, finned tube heat exchangers, distribution manifolds, and related accessories using stainless steel for 18 years. Stainless steel heat exchangers exhibit resistance to fouling, acid, corrosion, and wear, requiring minimal preventive maintenance and ensuring highly reliable performance. Stainless steel elements are stable, with a smooth surface that inhibits bacterial growth. Heat exchangers made from stainless steel find extensive applications in high cleanliness requirements, such as food and pharmaceutical industries. In plate heat exchangers, the working fluid flows through one side while the hot fluid flows through the other side, and then the cold fluid flows through the next side. This arrangement allows for thorough heat exchange within the heat exchanger, maximizing efficiency.