How does plate heat exchanger work?

2023-08-22 | Heat Exchanger

When it comes to efficiently transferring heat from one fluid to another, plate heat exchangers play a crucial role in various industries. In this blog post, we'll break down the workings of a plate heat exchanger in easy-to-understand terms, shedding light on its importance and applications.

Understanding Plate Heat Exchangers

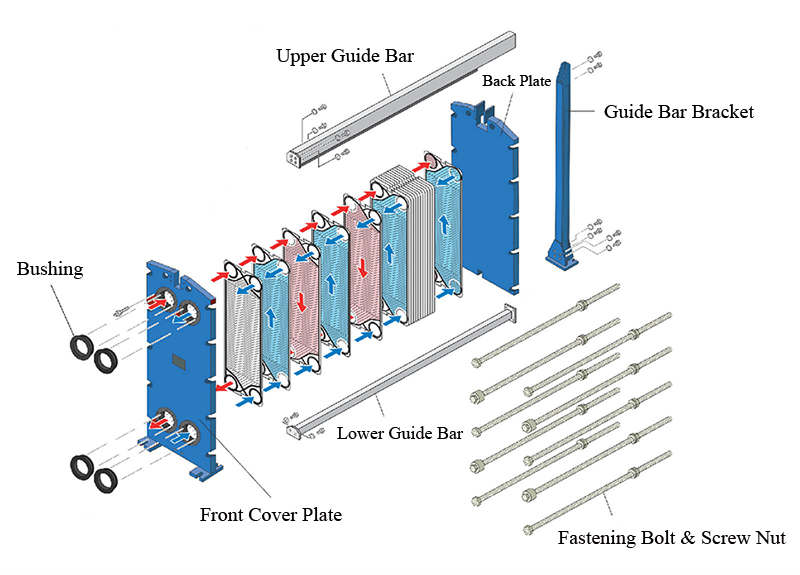

A plate heat exchanger is a compact and efficient device designed to transfer heat between two fluids without them coming into direct contact. It consists of a series of thin metal plates, typically made from stainless steel or other corrosion-resistant materials. These plates are stacked together, creating alternating channels for the hot and cold fluids to flow.

The Heat Exchange Process

The heat exchange process within a plate heat exchanger occurs in a few simple steps:

1. Fluid Flow:

The two fluids involved, known as the "hot fluid" and the "cold fluid," flow through their respective channels formed between the plates. The hot fluid is usually at a higher temperature than the cold fluid.

2. Heat Transfer:

As the fluids flow through their respective channels, heat is transferred from the hot fluid to the cold fluid through the thin metal plates. Since the fluids are separated by the plates, there is no direct mixing or contamination.

3. Efficient Design:

The design of the plates with their ridges and corrugations creates turbulence in the fluid flow. This turbulence enhances the heat transfer efficiency by minimizing the boundary layer and allowing for better thermal contact between the fluids and the plates.

4. Counterflow Principle:

Most plate heat exchangers use a counterflow arrangement, where the hot and cold fluids flow in opposite directions. This design maximizes the temperature difference between the fluids at any point, leading to a more efficient heat exchange.

Advantages and Applications

Plate heat exchangers offer several advantages, making them popular in various industries:

1. High Efficiency:

The efficient design and turbulent flow ensure optimal heat transfer, making plate heat exchangers highly efficient.

2. Compact Size:

The compact nature of plate heat exchangers makes them suitable for installations where space is limited.

3. Easy Maintenance:

The modular design of the plates allows for easy maintenance and replacement, minimizing downtime.

4. Versatile Applications:

These heat exchangers are used in applications such as HVAC systems, refrigeration, chemical processing, food and beverage production, and more.

In Conclusion

Plate heat exchangers provide a sophisticated yet simple solution for heat transfer needs across multiple industries. Their ability to efficiently transfer heat between fluids while maintaining separation makes them a go-to choice for many applications. Whether in large industrial processes or small-scale operations, the plate heat exchanger's compact design and efficient heat exchange process continue to play a vital role in improving energy efficiency and process performance.