What is a Heat Exchanger?

2023-08-18 | Heat Exchanger

Introduction

In the world of industrial processes, energy efficiency is a paramount concern. The ability to transfer heat from one medium to another efficiently is a fundamental aspect of many industrial operations. This is where heat exchangers step in. Heat exchangers are integral devices used across various industries to facilitate the efficient transfer of heat between fluids, ensuring optimal energy utilization and resource conservation. In this blog post, we will delve into the concept of heat exchangers, their types, working principles, applications, and their significance in modern industrial processes.

Understanding Heat Exchangers

At its core, a heat exchanger is a device designed to transfer heat from one fluid to another, without allowing the fluids to mix. Heat exchangers find application in a myriad of industries, including power generation, chemical processing, refrigeration, and air conditioning. These devices play a crucial role in facilitating processes that involve temperature regulation, energy recovery, and overall efficiency enhancement.

Types of Heat Exchangers

Heat exchangers come in various forms, each tailored to specific applications and requirements. Some of the most common types include:

1. Shell and Tube Heat Exchangers:

These consist of a series of tubes through which one fluid passes, surrounded by a larger shell through which the other fluid flows. The heat transfer occurs between the tube walls and the fluid inside.

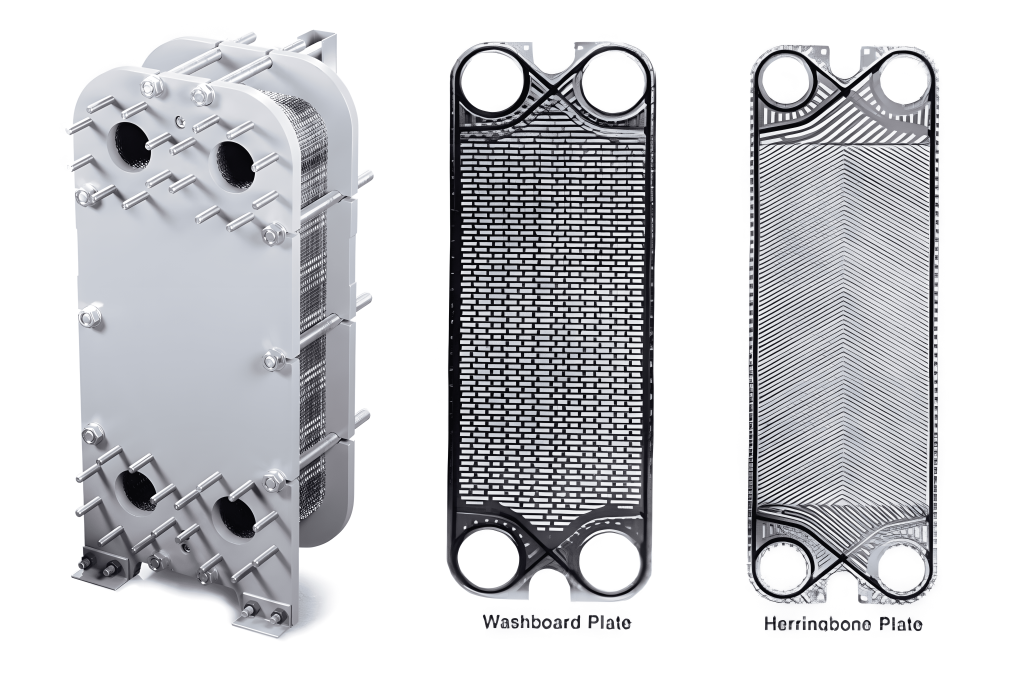

2. Plate Heat Exchangers:

These comprise a series of flat plates with alternating flow channels for the two fluids. Efficient heat transfer is achieved due to the large surface area of the plates and the controlled flow patterns.

3. Finned Tube Heat Exchangers:

These are used for air-to-fluid or fluid-to-fluid heat transfer and feature extended surfaces (fins) that increase the heat transfer surface area.

4. Double-Pipe Heat Exchangers:

Consisting of two concentric pipes, these are simple and compact devices commonly used for small-scale applications.

Working Principle

Heat exchangers operate on the principle of heat transfer from a higher-temperature fluid to a lower-temperature fluid. The two fluids can be in direct contact or separated by a barrier, depending on the application. Heat exchangers work to maximize the surface area available for heat transfer while minimizing energy losses due to conduction, convection, and radiation.

Applications of Heat Exchangers

Heat exchangers find extensive applications in various industries:

1. Power Generation:

Heat exchangers play a pivotal role in power plants, facilitating efficient cooling of steam in turbines and condensing the steam back to water.

2. Chemical Processing:

They are used in processes such as distillation, condensation, and evaporation, contributing to the overall efficiency of chemical reactions.

3. Refrigeration and Air Conditioning:

Heat exchangers are essential components in cooling systems, helping regulate temperatures in residential, commercial, and industrial spaces.

4. Process Industries:

Industries like petroleum refining, food processing, and pharmaceuticals rely on heat exchangers for precise temperature control and energy conservation.

Significance of Heat Exchangers

The importance of heat exchangers cannot be overstated. They enable efficient utilization of energy resources by recovering waste heat and transferring it to where it is needed. This not only reduces energy consumption but also has environmental benefits by minimizing greenhouse gas emissions. Additionally, heat exchangers enhance the overall efficiency of industrial processes, resulting in cost savings and improved productivity.

In Conclusion

Heat exchangers are a cornerstone of modern industrial processes, enabling efficient heat transfer between fluids in various applications. Their role in energy recovery, temperature regulation, and efficiency enhancement cannot be ignored. As industries continue to prioritize sustainability and energy efficiency, heat exchangers will undoubtedly remain indispensable tools for optimizing processes and conserving resources.