What is the difference between vertical and horizontal centrifugal pump?

2024-02-24 | Pump

In the realm of fluid dynamics, understanding the nuances between various types of centrifugal pumps is crucial. This blog delves into the distinctions between vertical and horizontal centrifugal pumps, shedding light on their unique characteristics and applications.

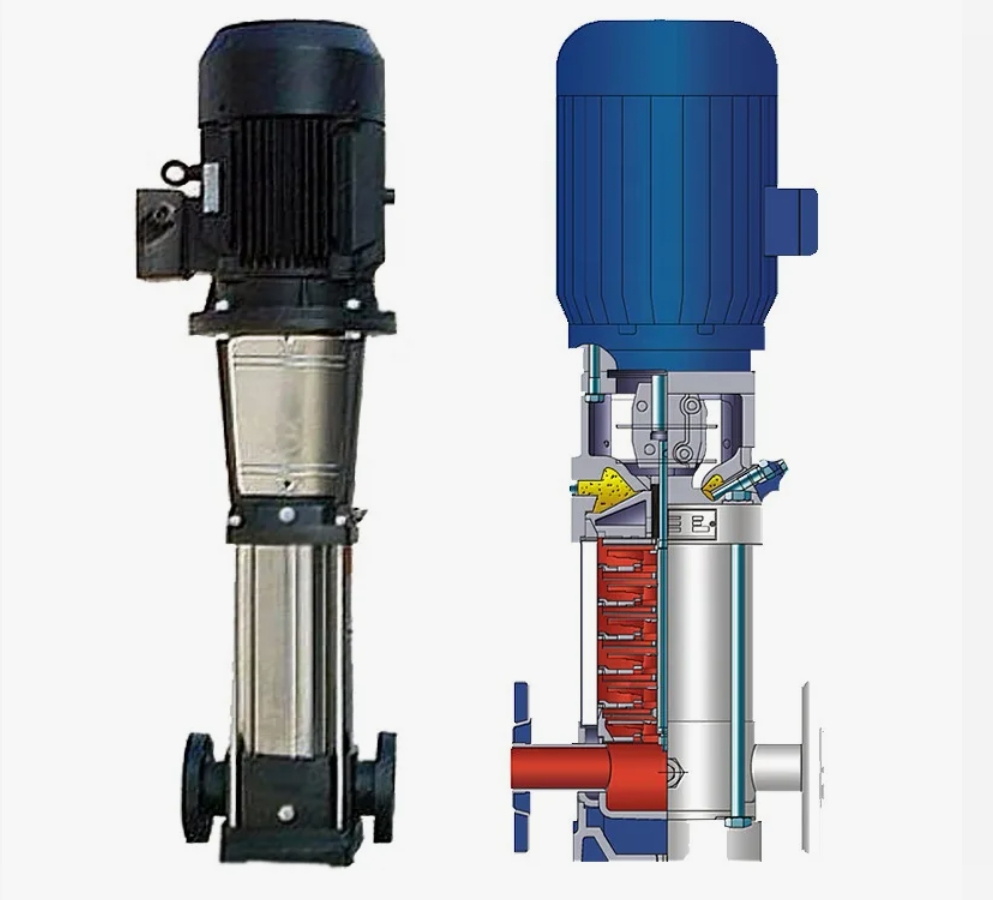

Vertical Multistage Centrifugal Pumps:

Vertical multistage centrifugal pumps are engineered for applications that require the transportation of fluids against significant head pressures. The vertical orientation of these pumps allows for space-efficient installations, making them particularly suitable for scenarios where floor space is at a premium. The modular design with multiple impellers stacked vertically enables customization to meet specific flow and pressure requirements.

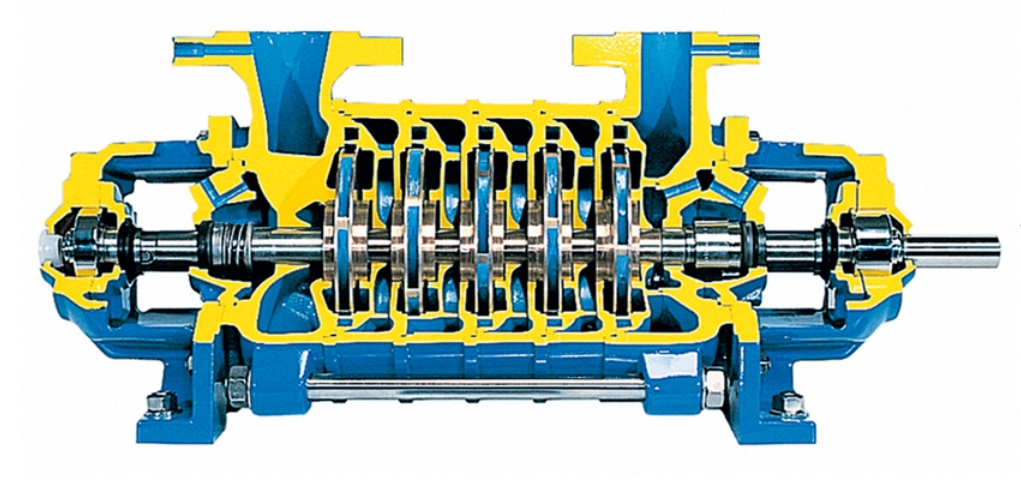

Horizontal Centrifugal Pumps:

On the other hand, horizontal centrifugal pumps are characterized by a side-mounted, horizontal shaft. These pumps are versatile and find applications in various industries. While they may not be as space-efficient as their vertical counterparts, they offer ease of maintenance and accessibility. Horizontal pumps are often used in applications where floor space is less of a concern, and the pump's accessibility is paramount for maintenance purposes.

Key Differences:

Understanding High Head and Multistage Pumps:

Both vertical and horizontal centrifugal pumps can be designed for high-head applications. High head refers to the capability of the pump to lift or push fluids to elevated points. In the case of multistage pumps, like the vertical multistage centrifugal pump, the fluid is passed through multiple impellers in stages, gradually increasing the pressure. This design is especially effective in scenarios where a single-stage pump might struggle to achieve the desired head.

Conclusion:

In the world of fluid transfer, the choice between vertical and horizontal centrifugal pumps depends on the specific requirements of the application. Vertical multistage pumps excel in situations where high head and space efficiency are paramount, while horizontal pumps offer versatility and accessibility for maintenance. Understanding these differences is key to optimizing pump selection for various industrial and commercial scenarios.